WHAT'S PRO-FILLING ?

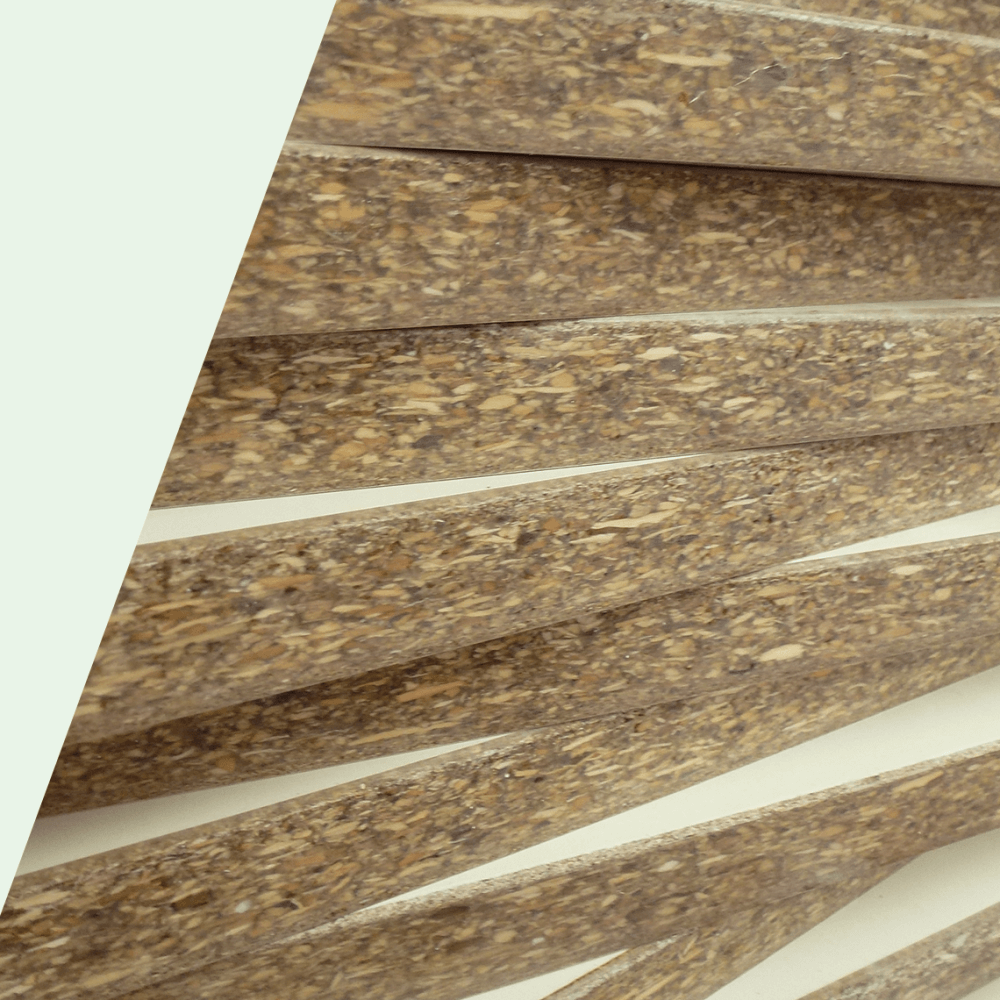

PRO-FILLING machines uses the technology of sealing the edges of particle board profiles, which results in the application of a high-quality finishing acrylic product.

The catalysis occurs through exposure to UV lamps.

PRO-FILLING TECH

The development of this technology comes directly from the need to compensate for particle board defects, sealing the material before painting or wrapping with papers, laminates or hi- gloss PVC.

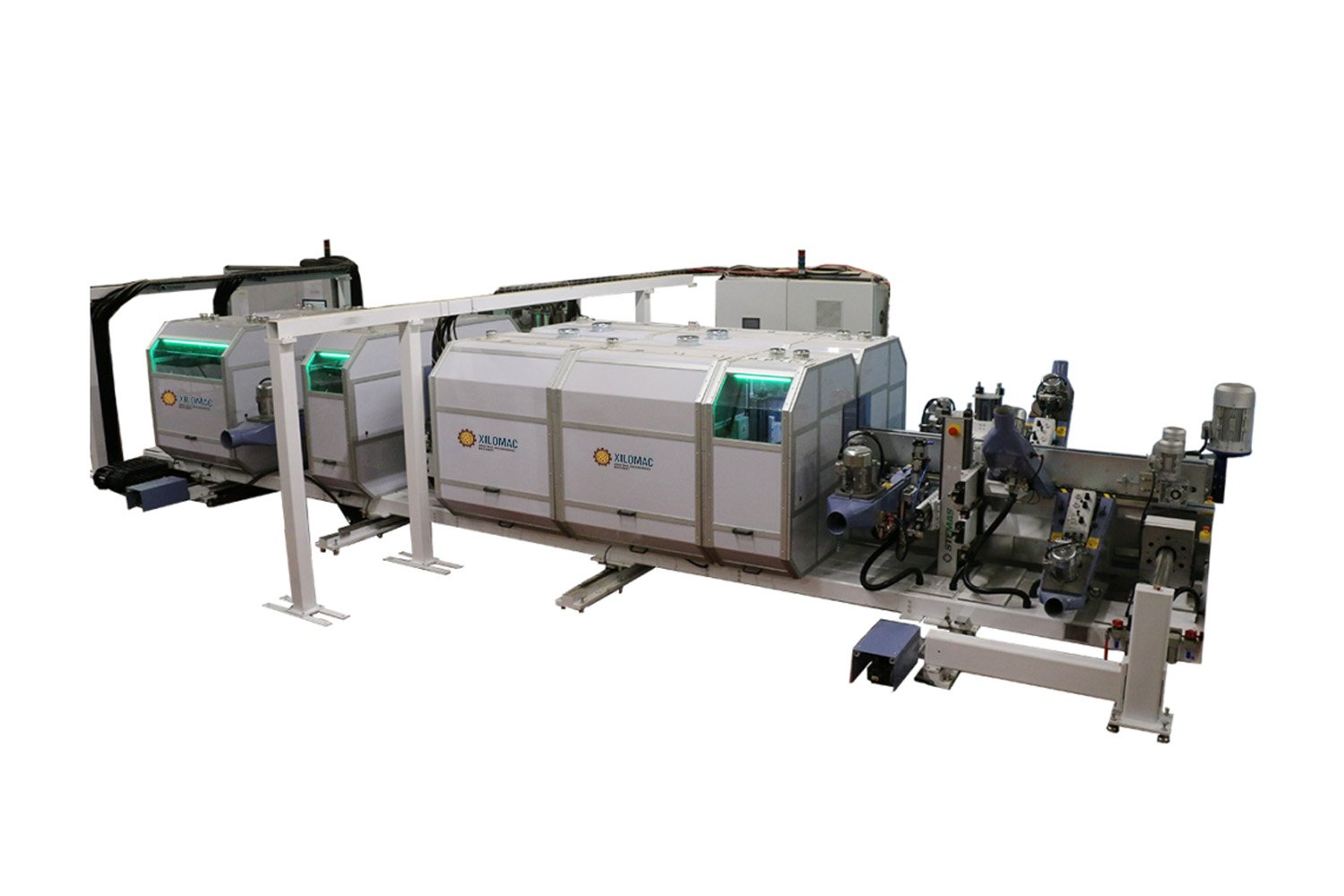

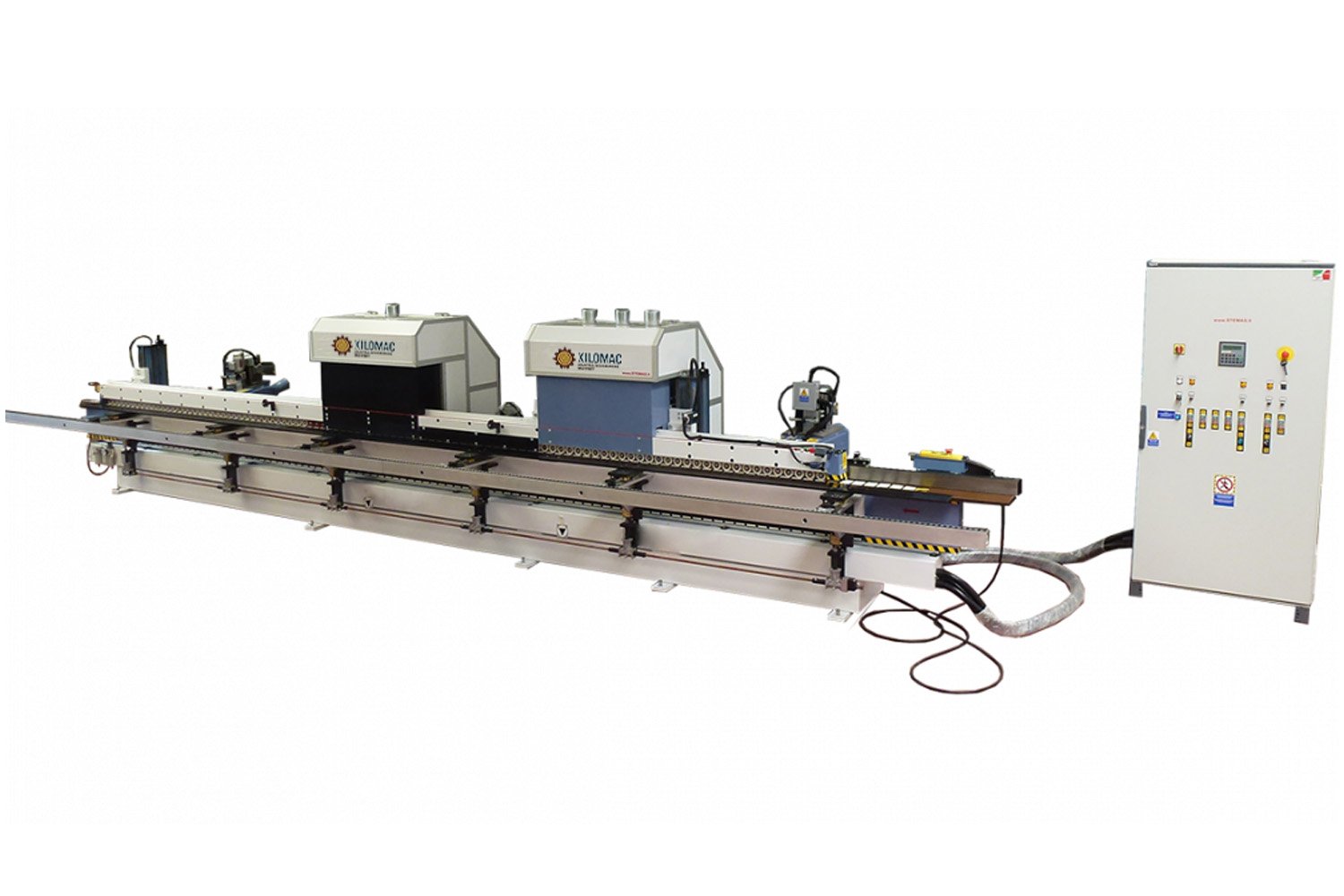

Stemas PRO-FILLING lines are able to work up to 100 meters/minute, and can be completed to perform profiling and sanding operations.

COST SAVING TECHNOLOGY

- This process makes the particle board quality higher compared to more expensive materials such as MDF.

- It also allows to use low-density particle board, therefore saving on transport weight.

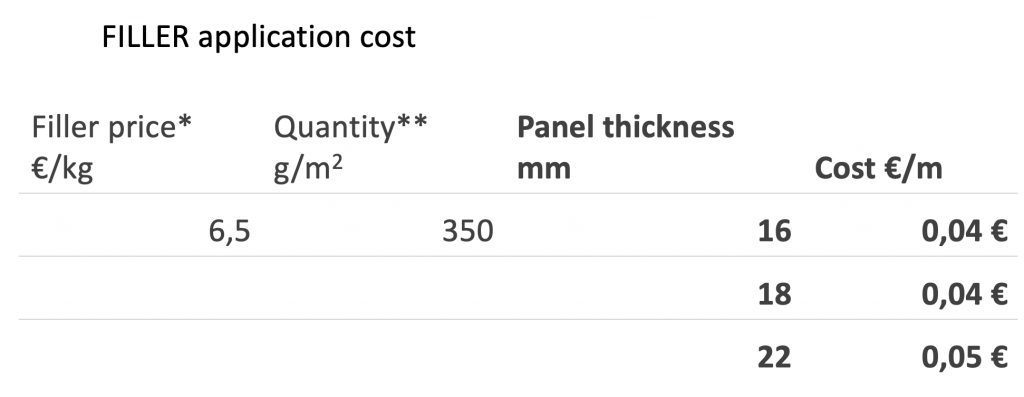

FILLER Application cost

*Stemas does not produce/sell filler. Simulation is made on average market price.

**Quantity can vary from 250 to 500 gr. depending on starting/finishing quality target.

A guide to correct use FEATURES

Phasellus dui enim, posuere ac porta non, convallis non eros. Mauris massa purus, ultricies vel venenatis in, cursus vitae tortor. Nam vehicula blandit velit, a fermentum elit blandit et.

OUR MACHINERY

评价

目前还没有评价