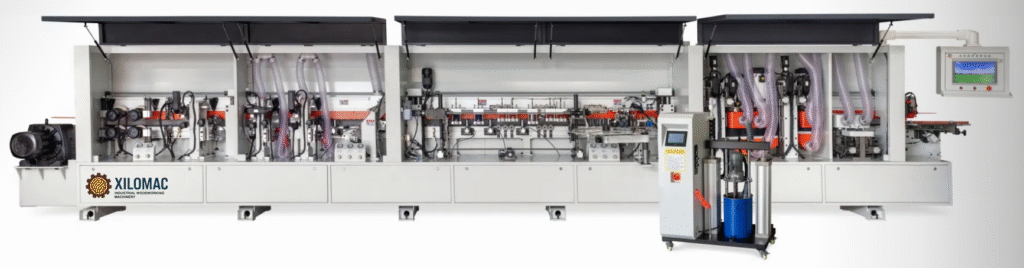

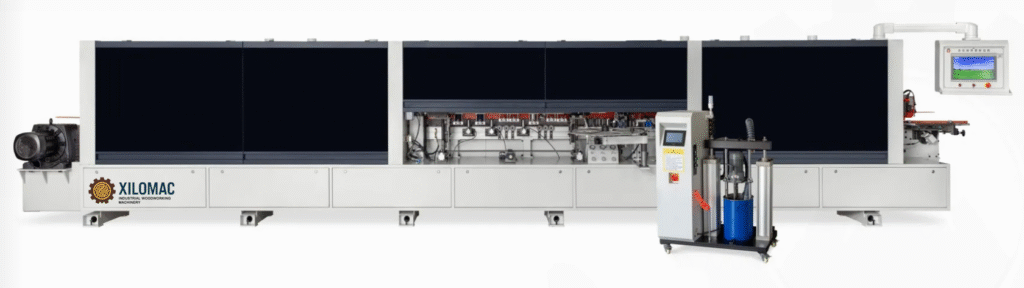

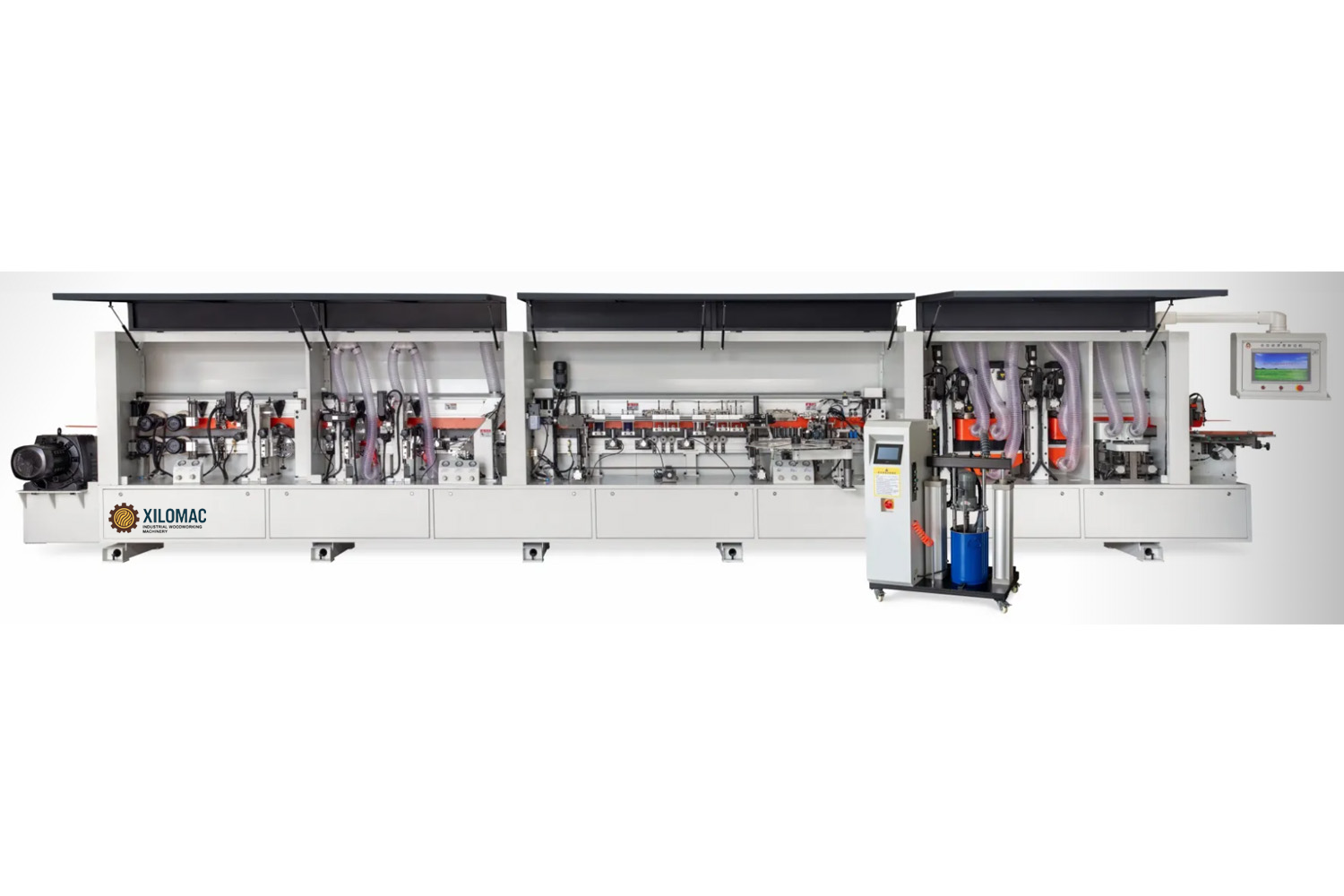

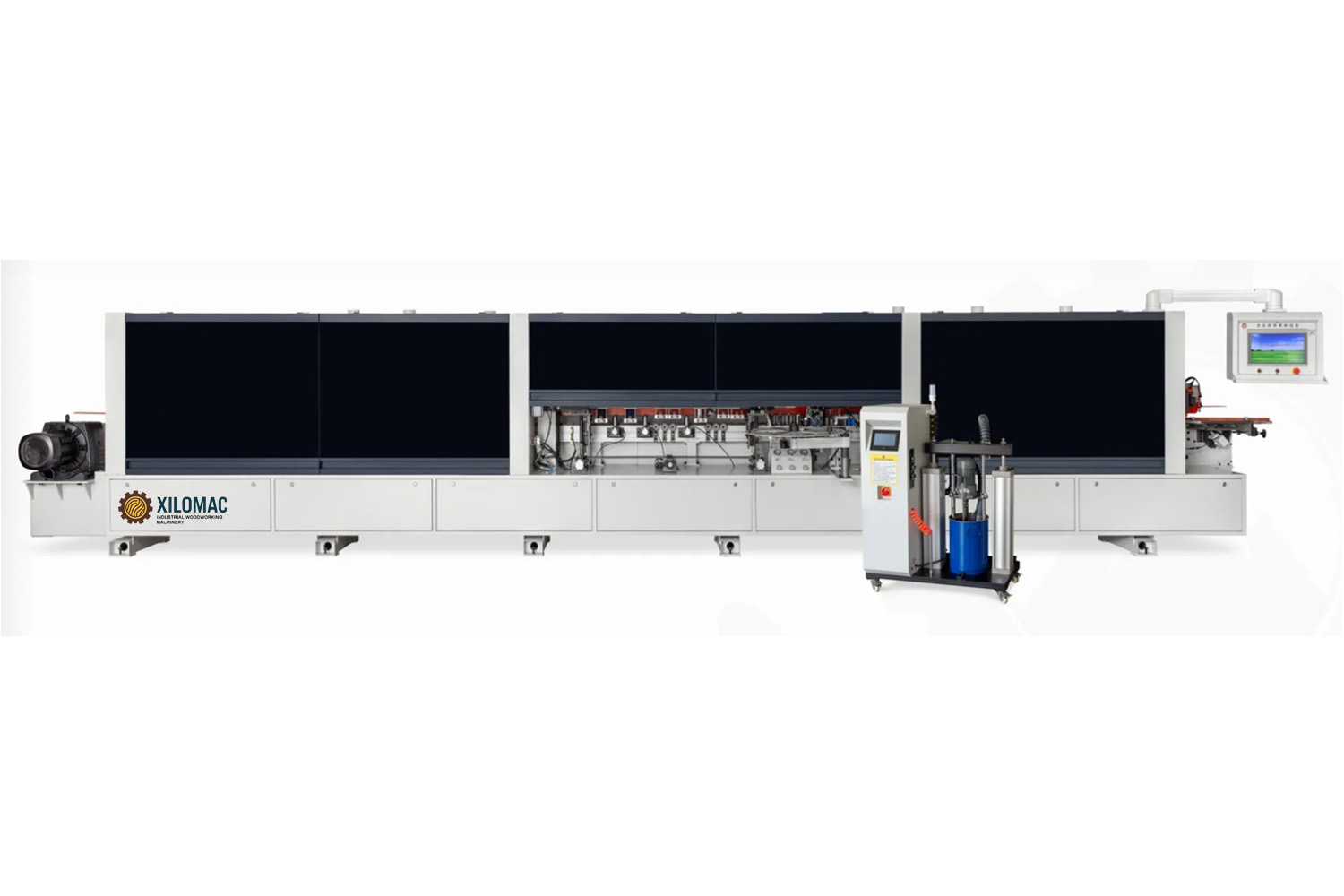

FUNCTION INTRODUCTION

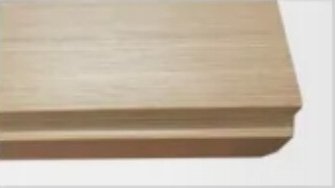

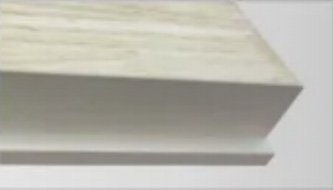

Slotting of edge banding strips; Pre milling; Servo rough milling; Servo precision milling; Quick – skeglue pot (coated with tape); Trim; Servo sub mother molding edge; Head aligned; Servo forward and backward rough trimming; Servo advance and retreat precision repair; Servo forward and backward edge scraping; Flexible flat scraping; Double polishing.

LOCAL ADVANTAGES

- Easy to operate, easy to adjust, high stability, beautiful design, safe and reliable.

- Large touch screen, clear display, multiple optimization of control logic, more user-friendly.

- Rough milling, precision milling, edge fitting, and edge trimming all use servo motors to meet the multiple size requirements of T – shaped wooden doors. The operation is simple, reducing human errors, and missing station adjustment or inadequate adjustment. The opening size can be set in advance and automatically adjusted, providing 5 formula settings to achieve one – click switching. The working size can be manually modified, and the servo motor can automatically modify the working position.

- Fast speed, high efficiency, saves space, and reduces labor costs.

评价

目前还没有评价